Ever wondered about the environmental impact of a product you're considering, beyond just how much energy it uses? An Environmental Product Declaration, or EPD for short, is like a report card that tells you exactly that.

Imagine an EPD as a label that goes beyond the usual features list. It breaks down the materials used in a product, letting you know what's inside. It even estimates the product's impact on global warming. This is becoming increasingly important because people are more interested in understanding the environmental footprint of what they buy.

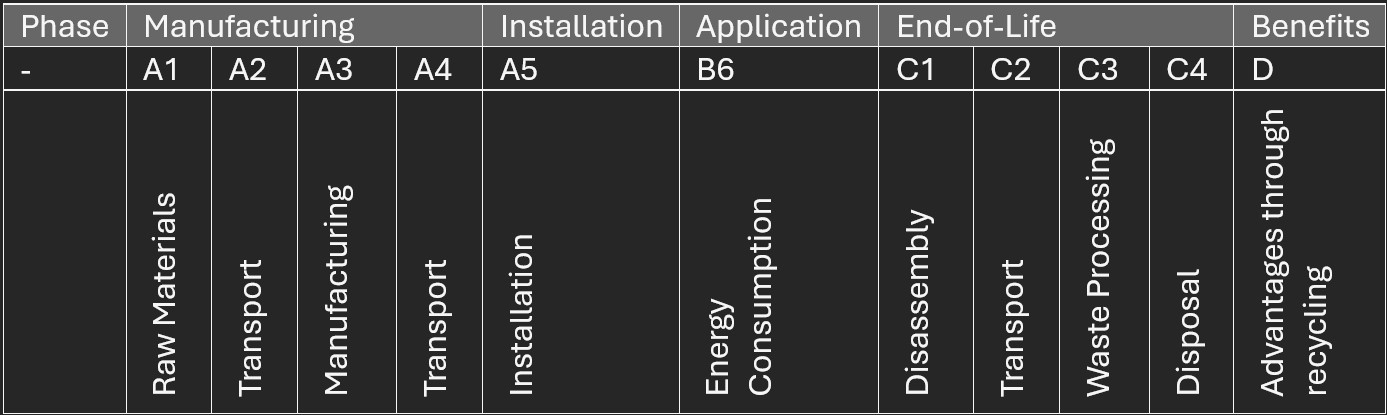

So why is this important in construction and lighting? Buildings are like giant collections of materials, sometimes called "urban mines." An EPD for a building material tells you what's in it, making it easier to figure out if those materials can be reused or recycled later. This, combined with the building's overall energy use and potential repairs, helps determine its lifetime environmental impact. It's like a checklist for building owners who want to be environmentally responsible. For those considering a "green building," an EPD is a valuable tool to make informed decisions based on facts.

In this interview, Heiko Becker, Head of ERCO’s Greenology Program shares with us ERCO’s EPD journey as a lighting manufacturer.

At ERCO, sustainability is more than a slogan—it's part of our core philosophy. Our Greenology program marries ecological responsibility with cutting-edge technology to create lighting solutions that respect both people and the planet.

We design luminaires for longevity, ensuring minimal waste and environmental impact. Each new product is engineered for a minimum 20-year lifespan. The durability of our 3-phase track system underscores our commitment to long-lasting, future-proof designs. But our focus extends beyond the product lifecycle; we're committed to carbon-neutral production and champion the principles of Human Centric Lighting for optimal well-being.

Our ultimate goal is carbon-neutral production. We achieve this by incorporating recycled materials, optimizing efficiency, and harnessing renewable energy. Decades of innovation have reduced energy consumption by 85%, and our facilities are now powered entirely by renewable sources. From our early daylight lab and green roof in 1988 to our current solar power system, ERCO has been a pioneer in sustainable lighting.

One of the greatest challenges in our pursuit of sustainability is shifting our focus from simply creating the best lighting technology to considering the entire product lifecycle and its environmental impact. Traditionally, lighting innovation centred on performance metrics like lumens and watts. However, true sustainability demands a holistic approach that encompasses material sourcing, manufacturing processes, and end-of-life considerations.

At ERCO, we've addressed this by meticulously examining our supply chain, implementing rigorous material assessments, and fostering transparent partnerships with suppliers. Beyond the product itself, we recognize that truly sustainable lighting involves understanding how light interacts with people. This is where human-centric lighting comes in. Human-centric lighting plays a pivotal role in creating healthier and more productive environments. By integrating these principles into our product development, we're not only reducing energy consumption but also enhancing the overall well-being of people.

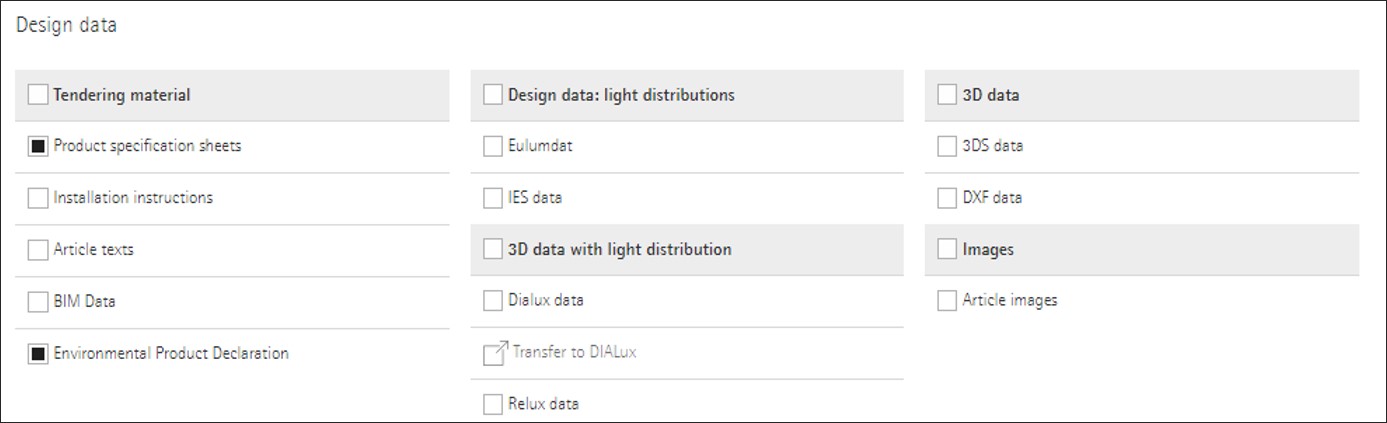

First and foremost, it's about transparency. We see a growing demand from customers who want to know exactly what they're buying. EPDs provide a clear picture of the materials used in our lighting solutions and their environmental impact. This aligns perfectly with our commitment to sustainability and empowers customers to make informed choices that align with their own values.

But EPDs aren't just a way to satisfy curiosity – they're a powerful tool for internal improvement. By analysing EPD data, we can see the environmental footprint of different parts of our manufacturing process, including our supplier network and production methods. This goes beyond simple efficiency and cost optimization. EPDs allow us to identify areas where we can make even more sustainable choices. For example, having a single production site minimizes transportation emissions. They're a springboard for continuous improvement on our path towards environmental responsibility.

EPDs are also key to helping us constantly improve and optimize both our products and their design. This optimization starts right from the beginning, with material selection and design decisions. By collecting data for future EPDs early in the development phase, we can consider materials, substances, and design with the environment in mind. This not only improves the product itself but also makes its manufacturing more sustainable.

EPDs empower specifiers with the information they need to make informed choices about the building materials they use. They can compare the environmental impact of different products and select those that align with their project's sustainability goals. EPDs also provide a clear picture of the materials used in a product, including their potential impact during both the use phase and end-of-life stage. This knowledge helps specifiers plan for responsible material management throughout the building's lifecycle.

All ERCO’s EPDs are Type 3 Environmental Product Declarations (EPDs), which means they are independently verified by a third party, adding a crucial layer of trust and transparency.

Data goes through a rigorous verification process throughout EPD creation. It might seem like a simple task, but even basic checks like confirming the total weight of all components matches the product's weight require close attention. With numerous parts and data sources (like suppliers), discrepancies can occur. That's why we have a comprehensive verification process in place, catching inconsistencies through meticulous checks.

This is just one example of the many steps we take to guarantee the transparency of the information you see in our EPDs. You can be confident that the data presented in our EPDs is accurate and reliable, allowing you to make informed decisions about the lighting solutions you choose.

Developing EPDs for our lighting products wasn't a simple task. It required a significant investment in both time and resources. The first step was securing management buy-in. We created a project scope document outlining the financial and labour commitment involved. After some thorough discussions about the total investment, we received the green light.

Next, we prioritized product groups. For the initial set (encompassing over 46,000 unique products!), we embarked on a detailed data collection process. This involved identifying every single component, its weight, transport distances and even the type of vehicles used for delivery.

Since most components and materials are handled within our own factory, the process also considered the energy consumption involved in production. We even factored in "leftovers" – materials that might be recycled or returned to the production line. Every detail, no matter how seemingly small, was meticulously documented.

Implementing EPDs for our lighting products wasn't without its hurdles. One of the biggest challenges, besides understanding the program itself and the specific rules for each product, was the sheer complexity. The vastness of our product portfolio and the intricate data involved required a dedicated approach.

To address this, we assigned a highly experienced senior project manager to lead the initiative. Their deep understanding of both our products and the available data proved invaluable in navigating this complex landscape.

Another hurdle was ensuring the availability of external resources. This included finding a qualified verifier for the final assessment and collaborating with our suppliers to gather the necessary information. Since EPDs were a new concept for many, we made a concerted effort to keep everyone informed throughout the entire project. Building strong relationships and fostering personal commitment from all parties involved – both internally and externally – was key to overcoming these challenges and achieving success.

The sheer amount of energy consumed by buildings today is undeniable. They're increasingly being viewed as "resource mines" for the future. This underscores the critical importance of collaboration among all stakeholders in the construction industry. For new subjects like sustainability, actively listening to stakeholders – architects, specifiers, and others – is even more crucial than with established practices. Keeping our ears and minds open allows us to anticipate future project needs and adapt accordingly.

Sustainability is a complex and evolving field, and EPDs hold great promise for improving the quality of equipment specifications. The vague term "or similar" often used in tenders creates challenges for everyone involved. EPDs will help clarify the true similarities between different products – how they're manufactured, how they perform, and how they're handled at the end of their lifespan. This increased transparency will make EPDs a go-to resource for both bids and purchasing decisions.

Quite simple, get started! I’m convinced that we need to consider the consequences of our actions more than in the past. It's a fact that resources – raw materials, energy, labour – are all finite. That's why we need tools to optimize their use, understand the impact of our actions, and constantly improve our processes.

Think about how often construction sites encounter problems because of unknown materials in old buildings or buried underground. In the future, with tools like EPDs and better documentation practices, we'll have a clear picture of the materials and substances used in construction. This will allow for responsible reuse, proper identification, and safe handling – a win-win for both the environment and construction efficiency.

By prioritizing timeless design, long-lasting products, and adaptability, we can make construction truly sustainable. This journey requires continuous learning, open communication, and a commitment to working together. It's an exciting path forward, and I believe EPDs will be a powerful tool in our collective toolbox.

Heiko Becker is a seasoned industry professional with a long-standing career at ERCO GmbH. With a deep-rooted expertise in product applications, he has been instrumental in numerous international projects. Initially focused on the technical intricacies of light measurement, Becker later broadened his role to encompass training and content development for ERCO’s global audience. A passionate advocate for sustainability, he has been a driving force both within the company and across the lighting industry. In 2023, Becker assumed leadership of ERCO's Greenology program, solidifying his commitment to environmental responsibility.