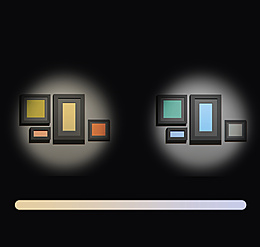

LED is the abbreviation for "Light Emitting Diode". This is a semiconductor device that emits light when direct current flows through it. The color of the generated light depends on the structure of the LED chip and the materials used. LEDs are temperature-sensitive dimmable point light sources that emit their light with hemispherical distribution towards the front.